2024-12-03 ペンシルベニア州立大学(PennState)

<関連情報>

- https://www.psu.edu/news/research/story/new-bioprinting-technique-creates-functional-tissue-10x-faster

- https://www.nature.com/articles/s41467-024-54504-7

- https://www.science.org/doi/10.1126/sciadv.aaw5111

スケーラブルな組織作製のためのスフェロイドの高スループットバイオプリンティング High-throughput bioprinting of spheroids for scalable tissue fabrication

Myoung Hwan Kim,Yogendra Pratap Singh,Nazmiye Celik,Miji Yeo,Elias Rizk,Daniel J. Hayes & Ibrahim T. Ozbolat

Nature Communications Published:21 November 2024

DOI:https://doi.org/10.1038/s41467-024-54504-7

Abstract

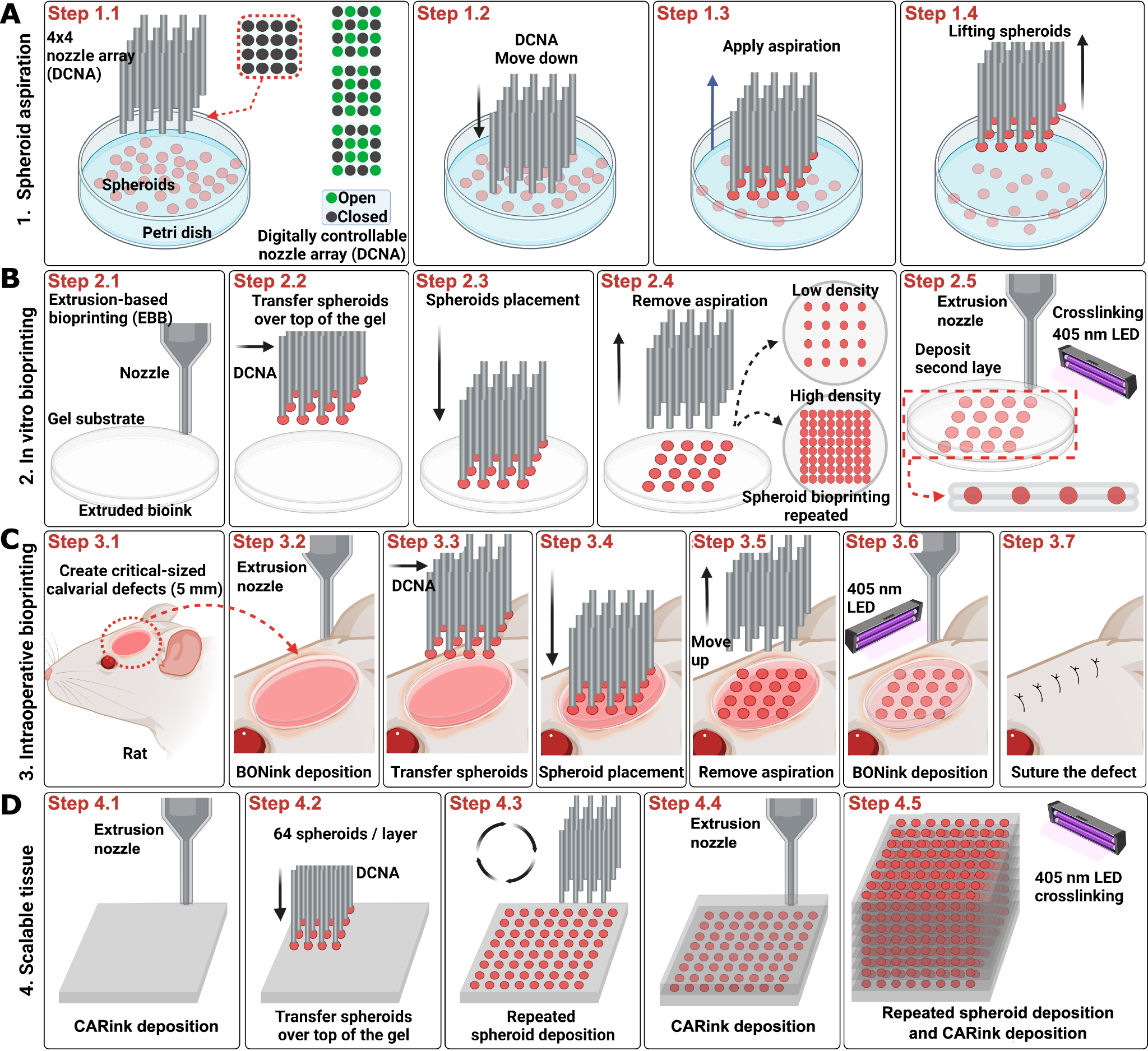

Tissue biofabrication mimicking organ-specific architecture and function requires physiologically-relevant cell densities. Bioprinting using spheroids can achieve this, but is limited due to the lack of practical, scalable techniques. This study presents HITS-Bio (High-throughput Integrated Tissue Fabrication System for Bioprinting), a multiarray bioprinting technique for rapidly positioning multiple spheroids simultaneously using a digitally-controlled nozzle array (DCNA). HITS-Bio achieves an unprecedented speed, ten times faster compared to existing techniques while maintaining high cell viability ( > 90%). The utility of HITS-Bio was exemplified in multiple applications, including intraoperative bioprinting with microRNA transfected human adipose-derived stem cell spheroids for calvarial bone regeneration ( ~ 30 mm3) in a rat model achieving a near-complete defect closure (bone coverage area of ~ 91% in 3 weeks and ~96% in 6 weeks). Additionally, the successful fabrication of scalable cartilage constructs (1 cm3) containing ~600 chondrogenic spheroids highlights its high-throughput efficiency (under 40 min per construct) and potential for repairing volumetric defects.

生物製剤の正確な位置決めのための吸引支援バイオプリンティング Aspiration-assisted bioprinting for precise positioning of biologics

Bugra Ayan, Dong Nyoung Heo, Zhifeng Zhang, Madhuri Dey, […], and Ibrahim T. Ozbolat

Science Advances Published:6 Mar 2020

DOI:https://doi.org/10.1126/sciadv.aaw5111

Abstract

Three-dimensional (3D) bioprinting is an appealing approach for building tissues; however, bioprinting of mini-tissue blocks (i.e., spheroids) with precise control on their positioning in 3D space has been a major obstacle. Here, we unveil “aspiration-assisted bioprinting (AAB),” which enables picking and bioprinting biologics in 3D through harnessing the power of aspiration forces, and when coupled with microvalve bioprinting, it facilitated different biofabrication schemes including scaffold-based or scaffold-free bioprinting at an unprecedented placement precision, ~11% with respect to the spheroid size. We studied the underlying physical mechanism of AAB to understand interactions between aspirated viscoelastic spheroids and physical governing forces during aspiration and bioprinting. We bioprinted a wide range of biologics with dimensions in an order-of-magnitude range including tissue spheroids (80 to 600 μm), tissue strands (~800 μm), or single cells (electrocytes, ~400 μm), and as applications, we illustrated the patterning of angiogenic sprouting spheroids and self-assembly of osteogenic spheroids.