2025-09-24 ロイヤルメルボルン工科大学(RMIT)

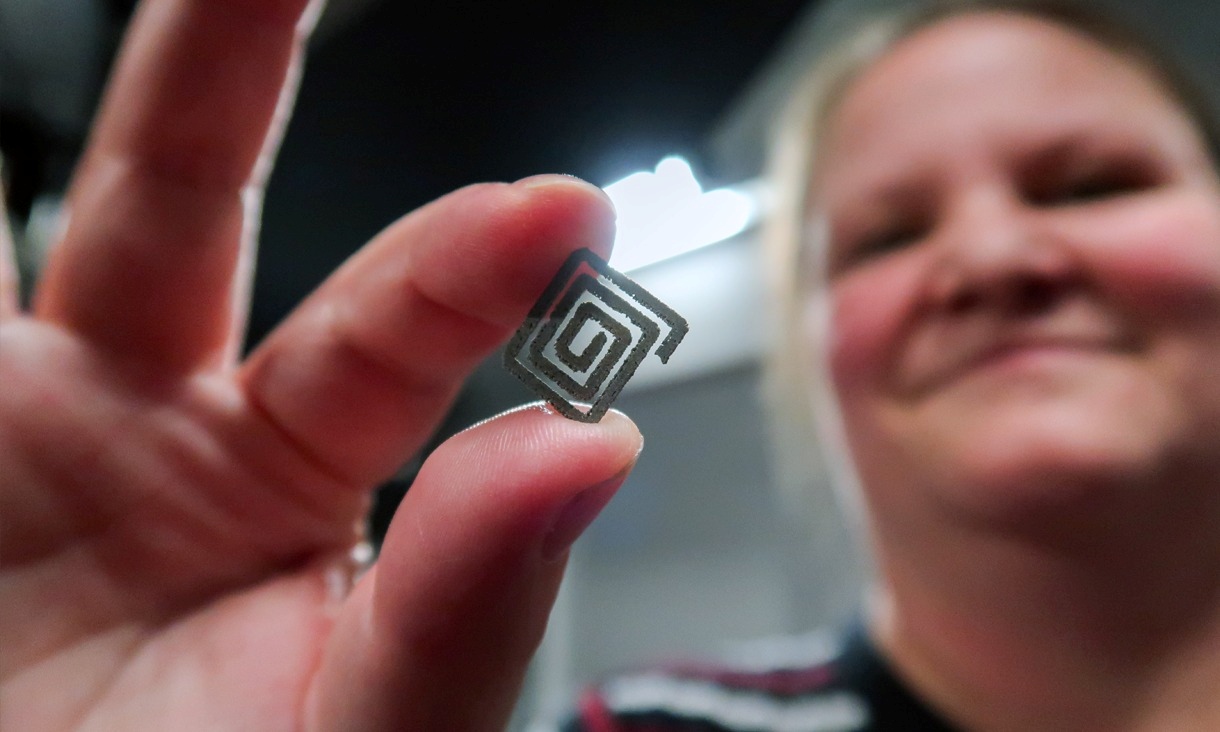

Professor Kate Fox from RMIT’s School of Engineering holds a spiral-shaped prototype of the diamond–titanium implantable device. Credit: Shu Shu Zheng, RMIT University

<関連情報>

- https://www.rmit.edu.au/news/all-news/2025/sep/diamond-power

- https://advanced.onlinelibrary.wiley.com/doi/10.1002/adfm.202508766

埋め込み型デバイス向けエネルギー回収・無線電力伝送用積層造形ダイヤモンド Additively Manufactured Diamond for Energy Scavenging and Wireless Power Transfer in Implantable Devices

Joshua Zarins, Daniel De Maria, Alan Jones, Deepak Sharma, Amir Ebrahimi, Zhangyu Xu, Omid Kavehei, Peter C. Sherrell, Kate Fox, Arman Ahnood

Advanced Functional Materials Published: 14 August 2025

DOI:https://doi.org/10.1002/adfm.202508766

Abstract

Additive manufacturing is revolutionizing personalized medicine by enabling prostheses and implantable devices that better match the body’s geometric constraints. This approach has primarily been used for mechanical implants, such as orthopaedic prostheses. Despite its clear benefits, additive manufacturing has not been used in microelectronic implants. This work introduces an additively manufactured diamond-titanium hybrid as a material for the construction of electronically active implantable devices. Wireless power transfer using inductive and capacitive coupling is demonstrated and used to induce localized tissue heating as well as to power up an light emitting diode (LED). At the macroscale, the diamond-titanium hybrid fulfils the requirements of traditional metallic biomaterials. At the nanoscale, the unique attributes of the hybrid material are used to demonstrate energy scavenging from the physiological flow of saline solution and its use for wireless flow sensing. In addition to fulfilling the structural role, additively manufactured diamond is a candidate material for use as part of microelectronic implants.