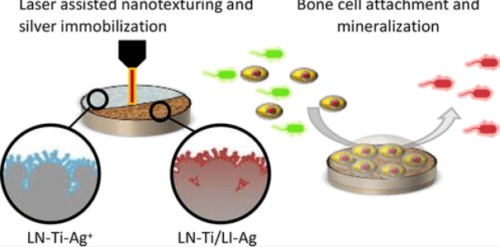

インプラント表面にナノ構造を形成するプロセスにより、骨細胞の付着も促進された。 Process to create nanostructures on implant surfaces also enhances bone cells’ attachment

2022-10-11 パデュー大学

パデュー大学材料工学部のRahim Rahimi助教授は、チタン製整形外科器具のインプラント表面に銀を固定化するプロセスを開発し、抗菌性と細胞統合性を向上させまた。

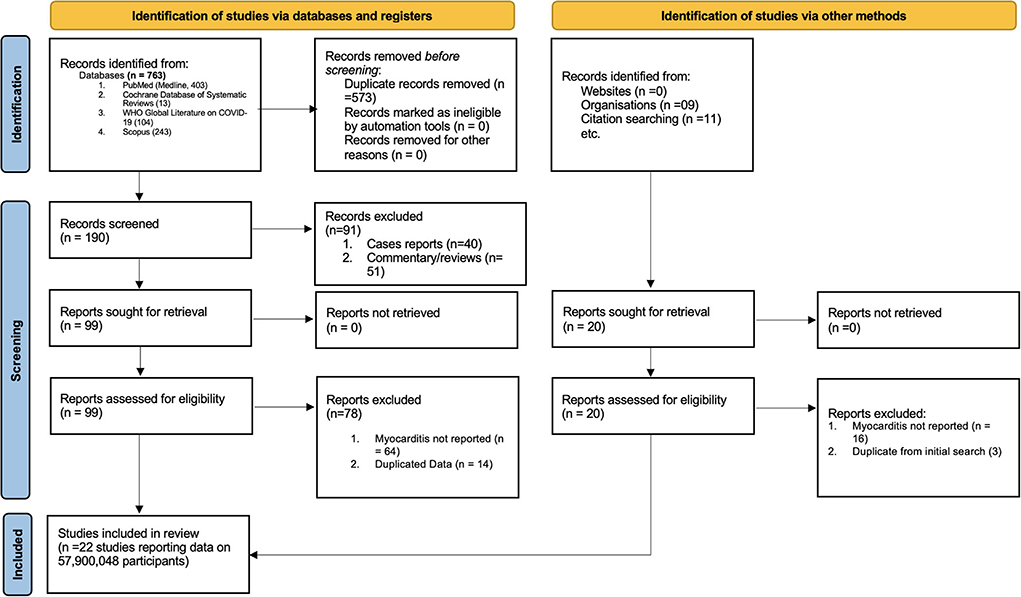

レーザーで銀を固定化したチタン表面の抗菌効果を、グラム陽性菌(黄色ブドウ球菌)およびグラム陰性菌(大腸菌)の両方に対してテストした。その結果、表面は6日以上にわたって効率的かつ安定した抗菌特性を示すことが確認された。また、レーザーナノテクスチャ加工されたチタン表面は、原型のままのチタンインプラント表面と比較して、オッセオインテグレーション特性が2.5倍向上していた。

2段階のプロセスのうち、最初のステップでは、チタンインプラント表面に階層的なナノ構造を形成し、骨細胞の接着を強化する。第2ステップでは、抗菌性のある銀をチタンインプラント表面に固定化する。

<関連情報>

- https://www.purdue.edu/newsroom/releases/2022/Q4/new-laser-surface-modification-process-with-silver-provides-antimicrobial-defense-to-titanium-orthopedic-devices.html

- https://pubs.acs.org/doi/10.1021/acs.langmuir.2c00008

チタンインプラント表面へのレーザー支援ナノテクスチャリングと銀の固定化により骨細胞のミネラル化および抗菌性を向上させた事例。 Laser-Assisted Nanotexturing and Silver Immobilization on Titanium Implant Surfaces to Enhance Bone Cell Mineralization and Antimicrobial Properties

Vidhya Selvamani, Sachin Kadian, David A. Detwiler, Amin Zareei, Ian Woodhouse, Zhimin Qi, Samuel Peana, Alejandro M. Alcaraz, Haiyan Wang, and Rahim Rahimi*

The ACS Journal of Fundamental Interface Science Published:March 21, 2022

DOI:https://doi.org/10.1021/acs.langmuir.2c00008

Abstract

Despite the great advancement and wide use of titanium (Ti) and Ti-based alloys in different orthopedic implants, device-related infections remain the major complication in modern orthopedic and trauma surgery. Most of these infections are often caused by both poor antibacterial and osteoinductive properties of the implant surface. Here, we have demonstrated a facile two-step laser nanotexturing and immobilization of silver onto the titanium implants to improve both cellular integration and antibacterial properties of Ti surfaces. The required threshold laser processing power for effective nanotexturing and osseointegration was systematically determined by the level of osteoblast cells mineralized on the laser nanotextured Ti (LN–Ti) surfaces using a neodymium-doped yttrium aluminum garnet laser (Nd:YAG, wavelength of 1.06 μm). Laser processing powers above 24 W resulted in the formation of hierarchical nanoporous structures (average pore 190 nm) on the Ti surface with a 2.5-fold increase in osseointegration as compared to the pristine Ti surface. Immobilization of silver nanoparticles onto the LN–Ti surface was conducted by dip coating in an aqueous silver ionic solution and subsequently converted to silver nanoparticles (AgNPs) by using a low power laser-assisted photocatalytic reduction process. Structural and surface morphology analysis via XRD and SEM revealed a uniform distribution of Ag and the formation of an AgTi-alloy interface on the Ti surface. The antibacterial efficacy of the LN–Ti with laser immobilized silver (LN–Ti/LI–Ag) was tested against both Gram-positive (Staphylococcus aureus) and Gram-negative (Escherichia coli) bacteria. The LN–Ti/LI–Ag surface was observed to have efficient and stable antimicrobial properties for over 6 days. In addition, it was found that the LN–Ti/LI–Ag maintained a cytocompatibility and bone cell mineralization property similar to the LN–Ti surface. The differential toxicity of the LN–Ti/LI–Ag between bacterial and cellular species qualifies this approach as a promising candidate for novel rapid surface modification of biomedical metal implants.