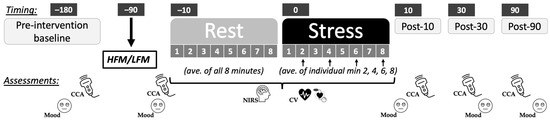

2023-12-07 デューク大学(Duke)

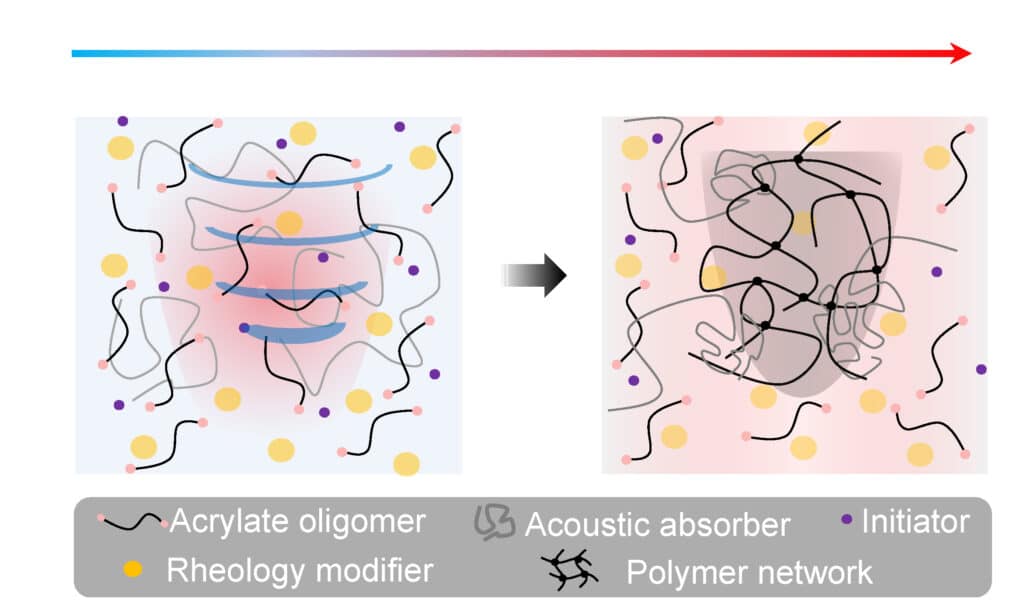

DAVP prints 3D constructs by curing sono-inks with focused ultrasound waves. The sono-thermal effect triggers the decomposition of the sono-inks to form polymer networks at the ultrasound focal zone. Image credit: Junjie Yao, Duke University; Shrike Yu Zhang, Harvard Medical School.

DAVP prints 3D constructs by curing sono-inks with focused ultrasound waves. The sono-thermal effect triggers the decomposition of the sono-inks to form polymer networks at the ultrasound focal zone. Image credit: Junjie Yao, Duke University; Shrike Yu Zhang, Harvard Medical School.

◆新しい印刷技術「DVAP」は、音波に反応する専用の「sono-ink」を使用し、超音波波によって硬化させることで、組織の深い部分に精密な構造を作成できるとされています。さまざまなテストで、心臓の閉鎖、骨の再構築、治療薬のデリバリーなどへの応用が可能であることが確認されました。

<関連情報>

- https://pratt.duke.edu/news/soundwaves-harden-3d-printed-treatments-in-deep-tissues/

- https://www.science.org/doi/10.1126/science.adi1563

自己増強型ソノインクが深部浸透音響体の印刷を可能にする Self-enhancing sono-inks enable deep-penetration acoustic volumetric printing

Xiao Kuang,Qiangzhou Rong,Saud Belal,Tri Vu,Alice M. López López,Nanchao Wang,Mehmet Onur Arıcan,Carlos Ezio Garciamendez-Mijares,Maomao Chen,Junjie Yao,and Yu Shrike Zhang

Science Published:7 Dec 2023

DOI:https://doi.org/10.1126/science.adi1563

Editor’s summary

Most methods for three-dimensional (3D) printing of polymers use focused light to control the formation of volume units (voxels). Kuang et al. developed a technique that they call deep-penetrating acoustic volumetric printing (DAVP), which uses a viscoelastic ink and high-intensity focused ultrasound (see the Perspective by Yao and Shapiro). A key feature of the technique is the sono-ink they used, which prevents curing beyond the focal point, thus preventing solidification beyond the intended voxel. A key advantage of using ultrasound is that it can penetrate multiple centimeters deep into opaque media. —Marc S. Lavine

Abstract

Volumetric printing, an emerging additive manufacturing technique, builds objects with enhanced printing speed and surface quality by forgoing the stepwise ink-renewal step. Existing volumetric printing techniques almost exclusively rely on light energy to trigger photopolymerization in transparent inks, limiting material choices and build sizes. We report a self-enhancing sonicated ink (or sono-ink) design and corresponding focused-ultrasound writing technique for deep-penetration acoustic volumetric printing (DAVP). We used experiments and acoustic modeling to study the frequency and scanning rate–dependent acoustic printing behaviors. DAVP achieves the key features of low acoustic streaming, rapid sonothermal polymerization, and large printing depth, enabling the printing of volumetric hydrogels and nanocomposites with various shapes regardless of their optical properties. DAVP also allows printing at centimeter depths through biological tissues, paving the way toward minimally invasive medicine.