2022-03-09 オークリッジ国立研究所

A team of researchers working within the Center for Bioenergy Innovation (CBI) at Oak Ridge National Laboratory has discovered a pathway to encourage a type of lignin formation in plants that could make the processing of crops grown for products such as sustainable jet fuels easier and less costly.

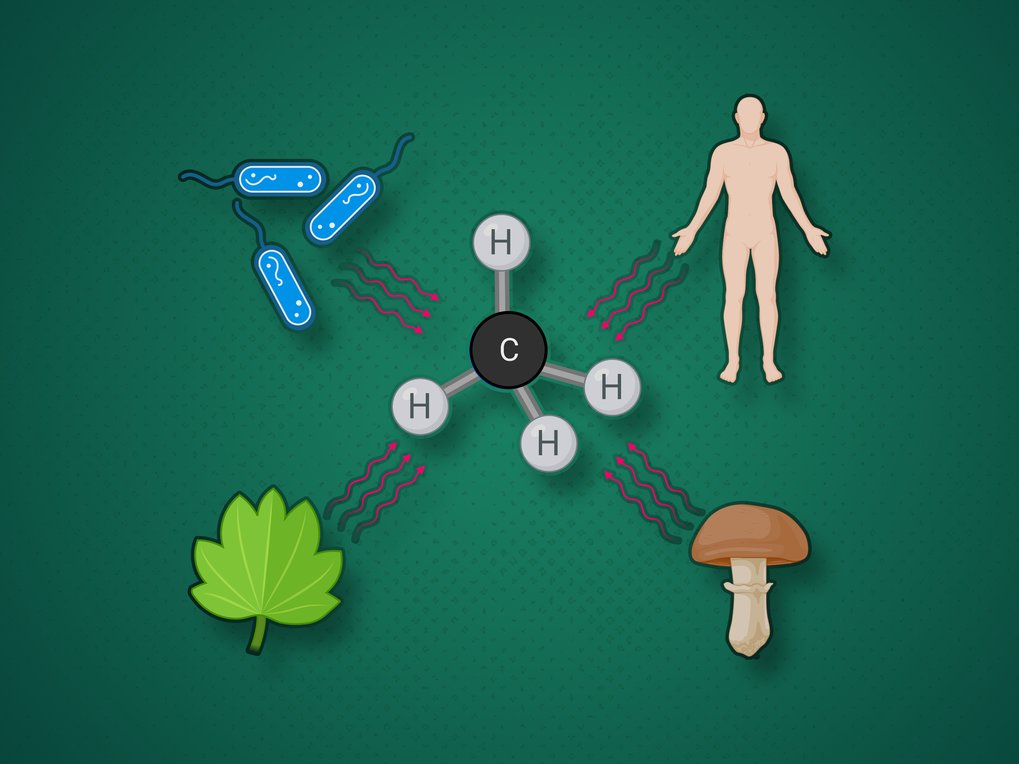

The researchers focused on C-lignin, a polymer in the seed coats of certain exotic plants. Lignin, the polymer that gives plants their rigidity, is a good source of the building blocks and aromatic chemical compounds needed to produce clean bio-based fuels. But lignin is also difficult to process, particularly the more common G- and S-lignins found in most plants.

C-lignin has a chemical structure that is more linear than the other lignins, making it easier to deconstruct. The scientists working as part of CBI, a U.S. Department of Energy Bioenergy Research Center, have now identified the genetic mechanism at play in the formation of this preferred C-lignin, as detailed in Science Advances. The scientists hope to engineer bioenergy crops to form C-lignin while constraining the growth of G/S-lignins, which could lead to more affordable, higher-yield bioprocessing.

The G/S lignins form polymer structures much like a fishing net with branches and kinks in it, while C-lignin is more of a string, explained Jerry Tuskan, CBI’s chief executive officer at ORNL. “You can imagine that it would be harder to pull apart a fishing net than a string that just unravels.”

Moving forward, Tuskan said the researchers want to engineer this polymer into their primary feedstocks of poplar trees and switchgrass as a means of making their cell walls easier to break down for conversion into sustainable aviation fuels.

The University of North Texas’ BioDiscovery Institute, a CBI partner and lead institution for the project, has been studying C-lignin for some time, since university researcher Fang Cheng first discovered the polymer’s presence in the seed coats of the vanilla bean in 2011.

“How do you make C-lignin in a plant that doesn’t normally make it?” asked Richard Dixon, Distinguished Research Professor of biological sciences at UNT. “We’ve been approaching this in two ways. One of them is sort of trial and error and making some guesses — putting it in the plants that don’t naturally make it and seeing what happens. The other is trying to really understand how C-lignin is made in a plant that does naturally make it.”

Scientists observe complete switch to C-lignin

Chunliu Zhuo, a postdoctoral scholar at UNT, recently made a new discovery about how plants make C-lignin while studying the cleome, or spider plant. Cleome makes G-lignin in its seed coats for about the first 12-14 days after pollination. Then it switches to making only C-lignin.

“You would imagine if cleome is switching from G-lignin to C-lignin at some point it might make mixed GC-lignin,” Dixon said. “It doesn’t. It’s pretty remarkable. It just switches completely.”

At ORNL, a team led by Tim Tschaplinski in the Biosciences Division informed the research with an analysis of C-lignin formation at the molecular level.

The scientists found that the building blocks for both types of lignin are still in the plants, but they don’t both connect to make the chains of lignin — a process known as polymerization. They are floating around in the cells but not binding together to make G/C-lignin.

“I was totally surprised by the G building blocks. We found that even later in the development, not any G-lignin is being made, but there is still a large amount of the G building blocks around. And they are still being made,” Zhuo said. “That drove us to look at how the plant does that. Why does it only make C-lignin when there is so much of the free G building blocks around?”

The researchers expected there to be a complicated process happening in the plant involving enzymes and multiple steps, but since the switch seems to be so sudden and so complete, they now think the process is actually much simpler than they previously thought.

“Since it happens all at once, and C-lignin has evolved recently in many plant species,” Dixon said, “it means it has to be simple.”

“It’s not as though 100 million years or 200 million years ago plants suddenly evolved C-lignin and now they all have it. It’s that some have it and some don’t, even if they are closely related species,” Dixon noted. “Chunliu has discovered that as soon as the plant makes the C building blocks, the conversion of the G building blocks into lignin is going to be inhibited.”

Discovery advances goal of better biomass crops

The researchers now believe that C-lignin building blocks work to prevent the formation of chains containing G building blocks. In understanding this mechanism, scientists are one step closer to developing crops with primarily C-lignin. If the process is that simple, then engineering it may be simpler than they thought. They would only have to introduce genes that turn on C-lignin, not turn it on and then inhibit the G-lignin, which is what they originally expected.

“It puts us closer to engineering plants with C-lignin in the sense that it tells us something that we don’t need to do — something we don’t need to worry about,” Dixon said.

“Until this discovery, C-lignin had been known as a smaller, minor component of the larger lignin molecules found in plant cell walls,” Tuskan said. “It had never been viewed as a large enough fraction to be of commercial importance. But now, by introducing C-lignin into cell walls we may be able to reduce the energy requirements for the deconstruction process. This work represents one of several steps towards an economically viable bioeconomy.”

The BioDiscovery Institute, one of UNT’s four institutes of research excellence, delivers solutions to underpin the utilization of plants, forest products and other biomass for production of biopolymers, new bio-based materials for construction and transportation, biofuels, and bioactive small molecules with applications in both agriculture and health care.

The Center for Bioenergy Innovation at ORNL is one of four DOE Bioenergy Research Centers focused on advancing biofuels and bioproducts for a vibrant domestic bioeconomy. The center is accelerating the development of bioenergy-relevant plants and microbes to enable production of drop-in sustainable aviation fuel, bioproducts that sequester carbon and sustainable replacements for plastics and other environmentally harmful products. CBI and this C-lignin research are supported by the Biological and Environmental Research program in DOE’s Office of Science.

UT-Battelle manages ORNL for DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science.

This story is adapted from an article by the University of North Texas BioDiscovery Institute.

Media Contact

Kimberly A Askey